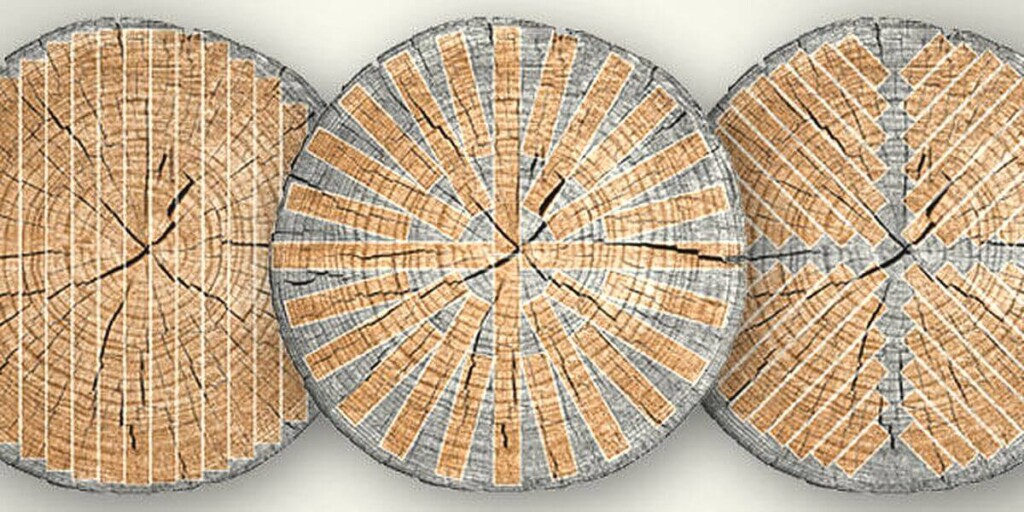

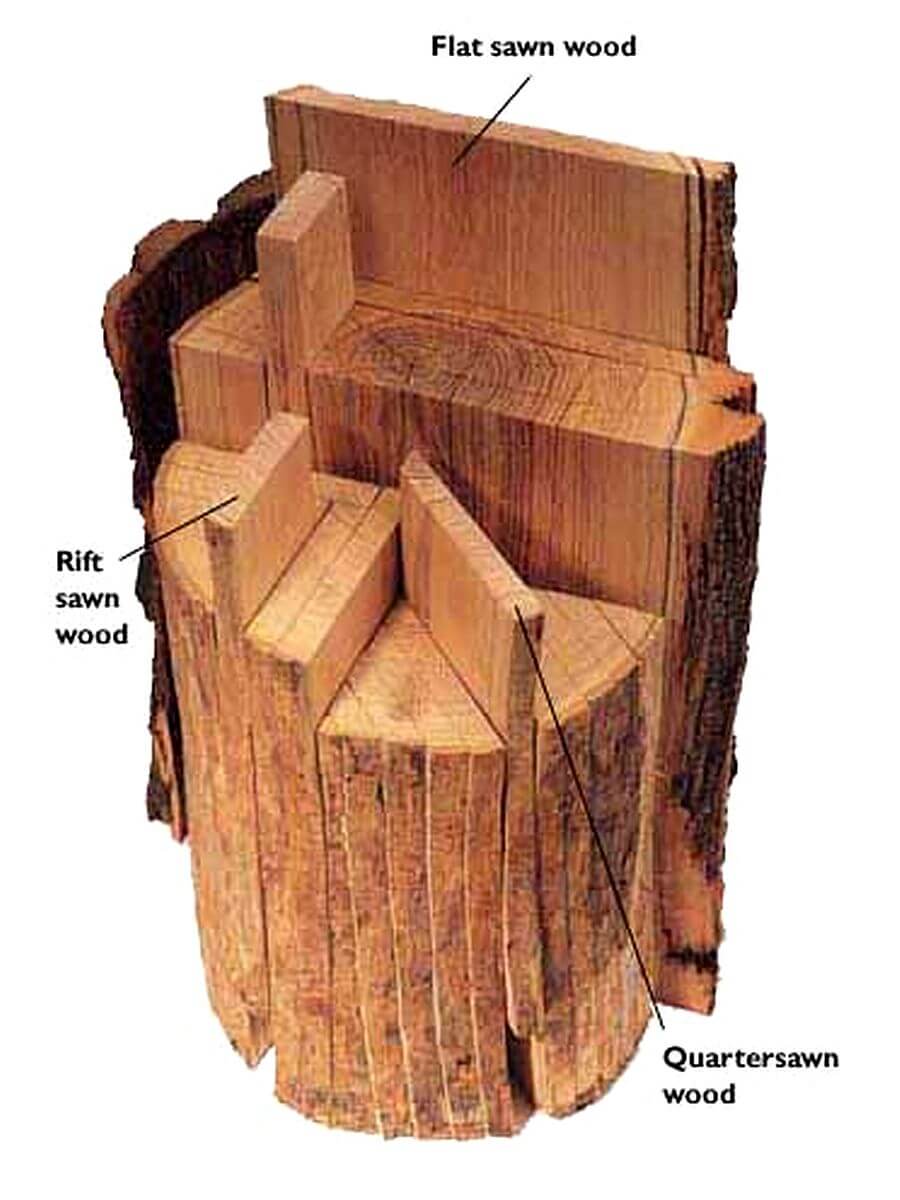

When lumber is cut from logs, it is typically cut in one of three ways: quarter sawn, rift sawn or plain sawn. Each type of lumber is dependent on how the log is oriented and cut at the sawmill. The result is a particular orientation of the growth rings on the end grain of the board and is what defines the type of lumber. The type of cut also determines the figure in a piece of wood and the wood’s mechanical properties.

Confused? Let’s take a look …

Plain Sawn, also called flat sawn, is the most common lumber sawn. It is also the most cost efficient method to manufacture logs into lumber.

The annular rings are generally 30 degrees or less to the face of the board; this is often referred to as tangential grain. The resulting wood displays a beautiful cathedral pattern on the face of the board. Plain sawn lumber is our standard at Tiny Timbers.

Each plank is cut straight through the log in one direction without changing the orientation of the log. This method produces boards with a full range of angles of the log’s rings, also known as the log’s “grain” and very wide boards. Generally, these angles range from zero to 90 degrees

Live sawn planks include a full range of the log’s characteristics, from the sought-after heartwood where the ring patterns are tightest to the sapwood. Due to the nature of wide boards comprising all the variable grains, live sawn lumber can present a challenge in the kiln drying process, sometimes with significant degrade.

Check out our specialty live sawn with live edge slabs.

Quarter sawn wood has an amazing straight grain pattern that lends itself to design. Quarter sawn lumber has annular growth rings that intersect the face of the board at a 60 to 90 degree angle. The log is sawn at a radial angle into four quarters, hence the name. Dramatic flecking is also present in red oak and white oak.

Quarter Sawn Advantages

Quarter sawn wood has an amazing straight grain pattern that lends itself to design. Often used for cabinetry, flooring, high-end custom crafts and furniture, it is the traditional wood used in making mission style furniture.

In addition to the desirable grain pattern, quarter sawn wood is dimensionally stable, making it ideal to work with and the recommended choice for flooring installed over hydronic heating systems.

Quarter sawn lumber exhibits almost no twisting, warping and cupping. It is more resistant to moisture penetration and less prone to surface checking and raised grain.

More dimensionally stable and beautiful to look at – is there a downside to it? In a word, yes. Because the manufacturing process results in a lower yield, requires larger prime logs and is more labor intensive to produce, the cost is higher and availability can be limited.

Most Expensive and Least Common

Rift sawn wood can be manufactured either as a compliment to quarter sawn lumber or logs can be cut specifically as rift sawn. In rift sawn lumber the annual rings are typically between 30-60 degrees, with 45 degrees being optimum. Manufactured by milling perpendicular to the log’s growth rings producing a linear grain pattern with no flecking. This method produces the most waste increasing the cost of this lumber. Rift sawn lumber is very dimensionally stable and has a unique linear appearance.

Rift sawn lumber is typically narrow with a very straight grain pattern on the face of the board. Rift sawn lumber is usually used with oak to avoid the flecks that are common in the species. Similar to quarter sawn lumber, rift sawn lumber is also referred to as radial grain. It is the most dimensionally stable and also the most wasteful to produce. Each of these boards is cut radially perpendicular to the growth rings of the tree. There are large triangles of waste left from between each board. As a result, rift sawn lumber is costly to produce and therefore, the most expensive type of planks available from a log.

Rift Sawn Advantages

Produces the strongest possible boards with the most consistent visual look of long and straight grain patterns. Generally the choice of cut for fine furniture makers looking for consistent patterns throughout their design.